Funded by the California Department of Transportation. Investigators – Y. H. Chai & Garry H. J. Hung (UC Davis), Peter Lee, John Drury & Darin Kishiyama (Caltrans).

Current bridge construction practice in California specifies two alternatives for the waiting time before the closure pour can be cast. The waiting time is intended to minimize the stress build-up in the closure slab arising from long term differential displacement between new and existing bridges, or between stage I and stage II bridges. The current waiting time is long and often leads to unnecessary delay before opening the bridge to traffic.

A long waiting period invariably leads to an increased construction cost and undue safety hazards during construction. Temporary K-rails typically placed at the edge of the bridge before closure impedes thetraffic flow and the longer these K-rails remains in-place, the higher the potential for traffic accidents. Careful considerations of time-dependent bridge deformation and its implication on the waiting period are therefore important for bridge widening or staged construction.

Waiting period currently specified by Caltrans does not take into account the displacement capacity of the closure slab and the time-dependent differential displacement that would be imposed on the closure slab. In this project, evaluation of the closure pour waiting time is undertaken in three steps. In step 1, a predictive model based on the creep compliance function is used to predict the time-dependent differential displacement across the closure slab for both staged construction and widening. The predictive model is shown to correlate well with field measured deflections for two box-girder bridges up to 12 months. In step 2, four full-size closure slabs were tested to determine the displacement capacities of typical California closure slabs. In step 3, a procedure based on the predictive model and laboratory determined displacement capacity is proposed to determine the waiting time for closure pour.

|

|

|

Santa Rosa Creek Bridge

|

San Jaoquin River Bridge

|

|

|

|

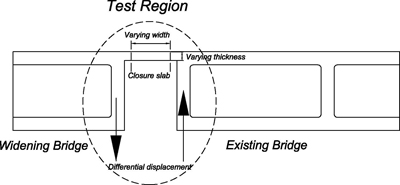

Closure slab test region

|

|

|

|

|

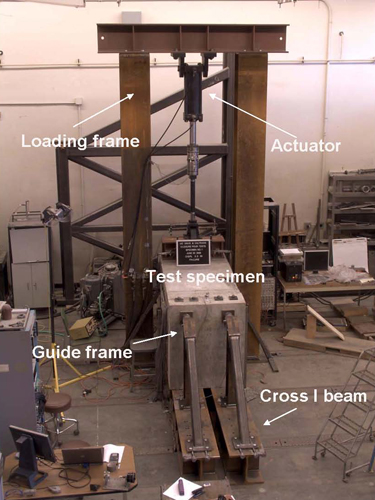

Final test setup

|

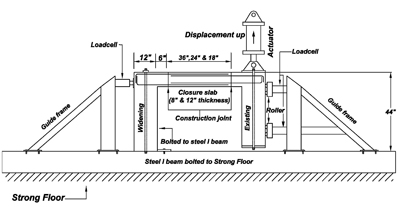

Schematic of closure slab test setup

|

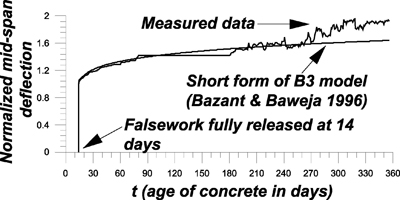

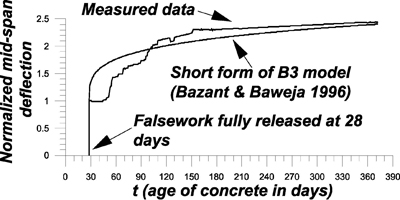

Optimum waiting time for closure pour requires a prediction of time-dependent deformation, which is invariably complex and involves the age of concrete at loading, ambient and curing conditions, type of cement, water-to-cement ratio, size and shape of the member, load duration etc. Initial time-dependent deflection upon falsework release can, however, be predicted using a creep-compliance function assuming correspondence between structural level deformation and material level deformation. Among various models available in the literature, the short form of the “B3” model proposed by Bazant and Baweja (1996) for concrete creep compliance is used to predict the differential displacement between new and existing bridges. The short form of the B3 model has been noted for its accuracy and simplicity for general use in design or field offices. A comparison between the measured deflection and that predicted by the B3 model is shown in the figures below.

Test results of four full-size closure slab specimens indicate that closure slabs in California exhibit rather brittle shear failure (see figures below). Special attention needs to be paid to stiff closure slabs, which are characterized by narrow width and large thickness, as brittle failures can be expected at small differential displacement. A methodology for determining the waiting period for closure can be formulated by requiring the displacement demand on the closure slab to be less than the displacement capacity of the slab. A shorter closure pour waiting time is generally permitted in a wide closure slab than a narrow closure slab. Closure for staged construction should also have a shorter waiting time compared to bridge widening, since the differential displacement between stage 1 and stage 2 bridges in staged construction is expected to be smaller than that of bridges during widening. Numerical examples indicate that a 60 days waiting period is unnecessary in many cases, and is especially true for bridges with small instantaneous displacements and in staged constructed bridges where differential displacement across the closure slab is small.

|

|

|

(a) Santa Rosa Creek Bridge

|

(b) San Joaquin River Bridge

|