In a PEM fuel cell stack, cells are arranged in series in order to produce sufficient power for practical application since a single cell typically has limited power output with less than 1 V of electrical potential. The fuel and oxidant are transferred to the cells in a stack through the stack manifold and the flow channels on the bipolar plate for each cell. The stack manifold and the flow channels together form a complex flow network. The flow distribution within a fuel cell stack is a major concern, which fuel cell designers are often faced with, since its effect on performance is significant. The performance degradation of a fuel cell stack has been known to be caused by unequal supply of fuel and oxidant through the stack manifold. Sufficient flow uniformity is crucial to diminish such degradation although limited space is allowed for the manifold in bipolar plate and necessary pumping power generally increases with increased flow uniformity.

A non-isothermal stack model has been developed to analyze the effects of flow variance and temperature distribution on the performance of a polymer electrolyte membrane (PEM) fuel cell stack. The stack model consists of the flow network solver for pressure and mass flow distributions for the reactant gas streams and cooling water, and the heat transfer solver for temperature distribution among the cells in the stack, as well as the fuel cell model for individual cell performance. Temperature, pressure and concentrations of fuel and oxidant are the most important conditions for the fuel cell operation. The results indicate that the effect of temperature is dominant on the cell voltage variance when the flow variance is small for sufficiently uniform distribution of reactant flow among the cells in the stack. Sufficient flow uniformity can be achieved by a large manifold that reduces the cell active area, or a small flow channel diameter, the latter may result in excessive pumping power for the anode and cathode gas streams. The manifold and flow channel diameters were optimized considering stack performance and reactant stream pumping power requirement. It is further shown that the flow and temperature distribution have a different influence on the stack performance, and a judicial matching of their distribution can provide the ideal uniform cell voltage distribution. An optimal combination of the flow and temperature distribution along the stack yields the optimal stack performance.

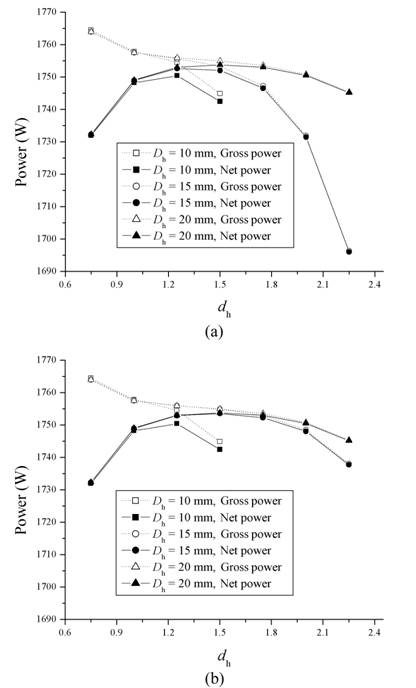

The gross and net stack output power for U and Z configuration stacks for various stack design parameters