We have modeled the two representative GDL materials, woven carbon cloth and carbon paper, via LB method. The true porous structure of carbon paper was directly taken from microscopic images. The permeability has been obtained for the various sample images of carbon papers and compared with the experimental measurements. We also present an unsteady two phase LB flow simulation which is applied to the study of liquid water removal from the porous electrode of a PEM fuel cell. We have modeled the two representative GDL materials, woven carbon cloth and carbon paper, via LB method. The true porous structure of carbon paper was directly taken from microscopic images. The permeability has been obtained for the various sample images of carbon papers and compared with the experimental measurements. We also present an unsteady two phase LB flow simulation which is applied to the study of liquid water removal from the porous electrode of a PEM fuel cell.

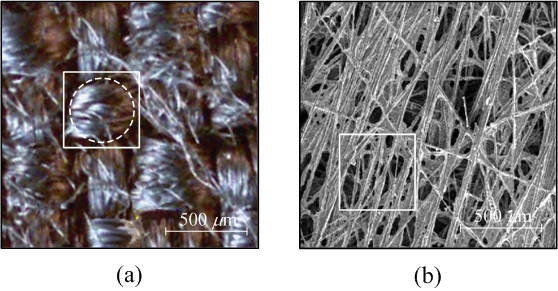

Microscopic pictures of the carbon gas diffusion media; (a) carbon cloth (a white square represents the computational domain and a white dotted circle the region of tow), (b) carbon paper (a white square represents the computational domain)

In a Proton Exchange Membrane (PEM) fuel cell, the pore of the gas diffusion layer is typically hydrophobic with the optimal value of polytetrafluoroethylene (PTFE) not to be congested with liquid water. However PTFE is an electrical insulator and high content of PTFE may reduce the conductivity and porosity of the electrode resulting in performance degradation. Such PTFE treatment could also result in inhomogeneous wetting condition in the GDL although existence of optimum hydrophilic condition may lead to the least mass transport losses. The performance of a PEM fuel cell is also significantly affected by the properties of the GDL such as thickness, permeability and surface conditions. A thin GDL with small porosity results in good electrical conductivity, however efficient mass transport requires large pores, i.e. large porosity.

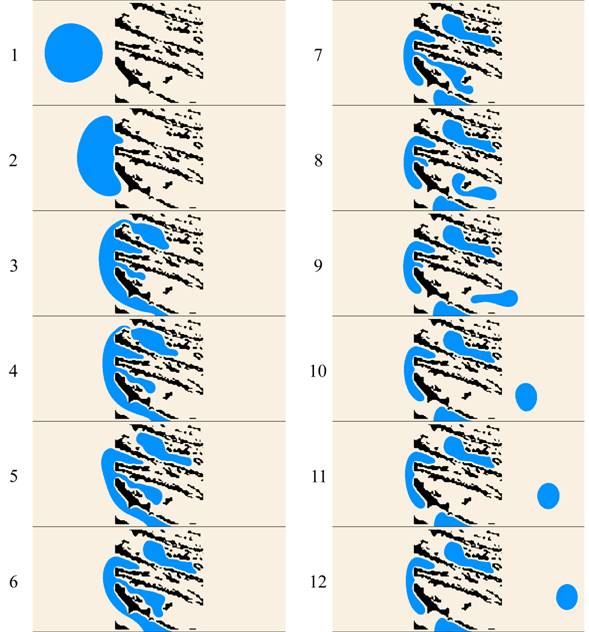

The convective flow of reactants is significant through the porous gas diffusion layer for the PEM fuel cells with interdigitated flow channel, serpentine flow channel and many of its modifications. Such reactant cross flow could play an important role for the removal of liquid water accumulated in the gas diffusion layer during operation. The following unsteady LB simulation result presents unsteady liquid water droplet behavior in a fibrous gas diffusion layer under pressure gradient.

Unsteady two-phase simulation results using LB binary fluid model simulating two-phase flow through fibrous structure of carbon paper GDL; blue area is the liquid bubble and black colored area indicates solid obstacle (carbon fiber). 1~2: liquid droplet starts to move, driven by the mean flow and hit the porous surface, 3~8: droplet deforms and breaks up into smaller ligaments moving into the porous region, 9~12: detached droplets leave the porous area while the major part of liquid water is trapped and remains in the porous area. ReL = 0.1, Ca = 2.3 × 10-5.