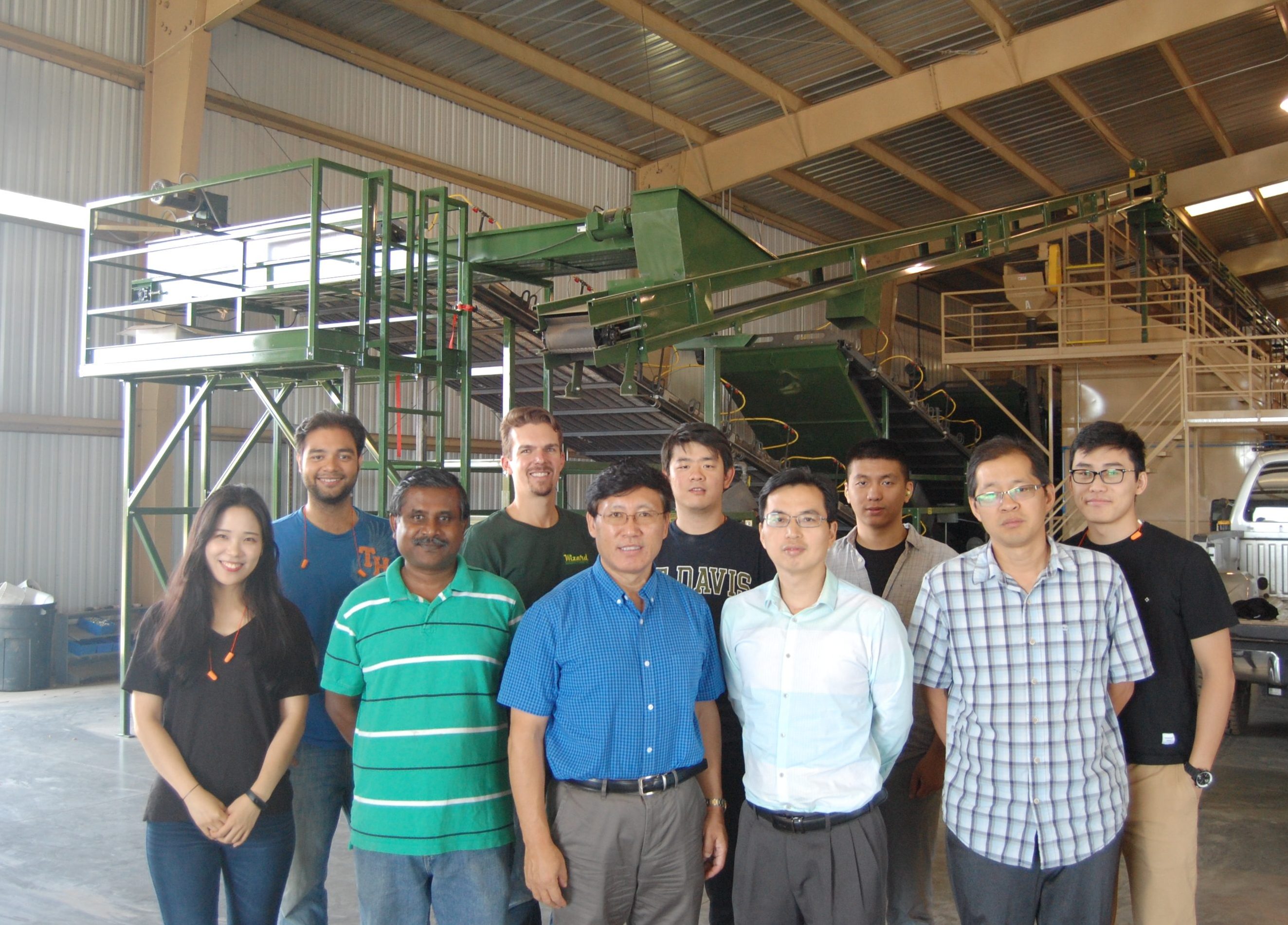

California produces 99% of the U.S. walnuts, amounting to 570,000 tons per year. Dr. Zhongli Pan’s research team discovered that the moisture contents of individual walnuts at harvest vary significantly, causing over-drying and under-drying problems. Over-drying results in a significant waste in energy and under-drying causes potential food safety risk due to microbiological growth concerns. Current hot air drying at low temperatures is energy intensive and slow. The team developed a new process by sorting walnuts into two to three groups based on moisture content using the different terminal velocities of the walnuts. Then the walnuts were dried by using infrared heating followed by hot air. The new method solved the over-drying and under-drying problems and significantly reduced the drying time and energy consumption by quickly removing the surface moisture. With the collaboration of Wizard Manufacturing Inc. the technology has been demonstrated at Emerald Farms in Maxwell, California at a commercial scale of 10-15 ton/h. The new drying method showed an energy saving up to 44% with improved quality and food safety through increased moisture uniformity of individual walnuts. This collaborative research project between the Healthy Processed Foods Research Unit, Western Regional Research Center, USDA-ARS and the Department of Biological and Agricultural Engineering, UC Davis is funded through a $1.18M grant from the California Energy Commission (CEC) and $280K from Wizard Manufacturing Inc., Chico, CA and supported by Emerald Farms.

Energy Efficient and High Speed Infrared Drying of Walnuts

Bookmark the permalink.