Traditional hot water and steam blanching and hot air drying are essential for the processing of fruits and vegetables to preserve the product quality and extend the shelf life. The long processing time may negatively affect the product quality. The large amounts of water and energy consumption and the need for wastewater disposal make the process not sustainable. Our research team developed a new simultaneous IR dry-blanching and drying (SIRDBD) technology that eliminates the water or steam used in traditional blanching and reduces energy use. The technology utilizes IR energy to simultaneously inactivate enzymes and dry the products. The SIRDBD technology has been applied for different food products such as strawberries, bananas, and apples and obtained better product quality compared to conventional methods.

|

|

|

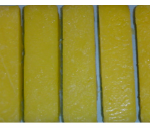

| Pilot Scale of SIRBD Equipment | Frozen whole apple bars produced after SIRDBD | Frozen whole strawberry bars produced after SIRDBD |

Selected Publications:

Wu, B., Z. Pan, J. Wang, H.M. El-Mashad, B. Wang, and H. Ma. 2018. Drying performance and product quality of sliced carrots by infrared blanching followed by different drying methods. International Journal of Food Engineering. 10.1515/ijfe-2017-0384. https://doi.org/10.1515/ijfe-2017-0384.

Ma. H., J. Wang, B. Liu, Z. Pan., B. Wu, H. Chen, Y. Ding, and R. Liu. 2015. Experiment and dynamics of dehydration and inactivation of enzyme of potato slices by simultaneous infrared dry-blanching. Transactions of the Chinese Society of Agricultural Engineering. 31(7):304-310.