The peeling process is a vital sector of the fruit and vegetable processing industry. Traditional hot-lye and steam peeling have drawn increasing concerns regarding water and energy consumption, need for proper management of high organic load and salinity wastewater, and negative environmental impacts. Therefore, development of alternative sustainable peeling methods to reduce the use of chemicals and water, while maintaining or enhancing the product quality is very important. Our research team focuses on using IR heating for the peeling of different fruits such as tomato, pears, peaches and jujubes, etc. .

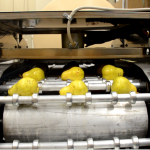

IR dry-peeling of Tomato

- Compared with lye peeling, IR dry-peeling yielded lower peeling loss (8.3% -13.2%) and firmer products (1.05 – 2.01 N), while having a similar ease of peeling and processing time.

- During IR heating, the substantial biomechanical changes in treated skins were characterized by reduced adhesive energy, increased dynamic moduli, and shifted transition temperature.

- Peel loosening was resulted from reorganization of extracellular cuticles, thermal expansion of cell walls, and collapse of several cellular layers.

- Peeling performance can be enhanced through using emitters with variable intensity and presorting tomatoes according to size

(click the thumbnails for original pictures)

|

|

|

IR dry-peeling of Pear

- High peeling yield (94.44%) and little peeling losses (9.89% to 13.80%) were achieved for pears.

- All pears with proper firmness for canning can be peeled with IR heating.

(click the thumbnails for original pictures)

|

|

|

IR-dry peeling of Peach

- Compared with lye peeling, the IR dry-peeling method showed promising results in achieving high peelability (>80 mm2/100 mm2 or %) and high peeling yields (>90 g/100 g or %), while ensuring that the peeled products have desirable color and texture characteristics.

- Significant improvements in peelability and peeling yields were achieved with the use of high IR intensity.

IR dry-peeling of Jujube

- Optimal peeling conditions for jujubes were IR radiation intensity of 5.25 W/cm2, emitter distance of 75 mm and heating of 56s.

- Peelability, easiness, moisture loss and surface temperature were found to be 96%, 3.8, 1.29% and 115 ℃.

- Compared to the hot lye peeling, the IR dry-peeling of jujubes significantly reduced peeling loss and color change at a similar satisfactory peelability (>96%).

Selected Publications:

Vidyarthi SK, HM El Mashad, R Khir, R Zhang, G Sun, R Tiwari, Z Pan. 2020. Viscoelastic properties of tomato peels produced from catalytic infrared and lye peeling methods. Food and Bioproducts Processing. 119: 337-344. https://doi.org/10.1016/j.fbp.2019.11.019.

Vidyarthi, S., H.E. El-Mashad, R. Khir, R. Zhang, T.H. McHugh, and Z. Pan. 2019. Tomato peeling performance under pilot scale catalytic infrared heating. Journal of Food Engineering. 246:224-231. https://doi.org/10.1016/j.jfoodeng.2018.11.002.

Vidyarthi, S., H.E. El-Mashad, R. Khir, R. Zhang, and Z. Pan. 2019. Quasi-Static mechanical properties of tomato peels produced from catalytic infrared and lye peeling. Journal of Food Engineering. 254:10-16. https://doi.org/10.1016/j.jfoodeng.2019.03.001.

Vidyarthi, S., H.E. El-Mashad, R. Khir, R. Zhang, R. Tiwari and Z. Pan. 2019. Evaluation of selected electric infrared emitters for tomato peeling. Biosystems Engineering. 184:90-100. https://doi.org/10.1016/j.biosystemseng.2019.06.006.

Vidyarthi, S., H.E. El-Mashad, R. Khir, S.K. Upadhyaya, S.K. Singh, R. Zhang, R. Tiwari, and Z. Pan. 2019. A mathematical model of heat transfer during tomato peeling using selected electric infrared emitters. Biosystems Engineering. 186:106-117. https://doi.org/10.1016/j.biosystemseng.2019.07.001.

Wang, B., C. Venkitasamy, Z. Pan, L. Zhao, and Q. Huang. 2016. Feasibility of jujube peeling using novel infrared heating technology. LWT – Food Science and Technology. 69:458-467. https://doi.org/10.1016/j.lwt.2016.01.077.

Pan, Z., X. Li, R. Khir, H.M. El-Mashad, G. Atungulu, T.H. McHugh, and M. Delwiche. 2015.A pilot scale electrical infrared dry-peeling system for tomatoes: design and performance evaluation. Biosystems Engineering. 137:1-8.

Li, X., Pan, G.G. Atungulu, X. Zheng, D. Wood, M. Delwiche, and T.H. McHugh. 2014. Peeling of tomatoes using novel infrared radiation heating technology. Innovative Food Science and Emerging Technologies. 21:123-130.

Li, X., Pan, G.G. Atungulu, D. Wood, and T.H. McHugh. 2014. Peeling mechanism of tomato under infrared heating: peel loosing and cracking. Journal of Food Engineering. 128:79-87.

Li, X, and Pan. 2014. Predictive modeling of infrared radiative heating in tomato dry-peeling process: Part I. Model development. Food and Bioprocess Technology: An International Journal. 7:1996-2004.

Li, X, and Pan. 2014. Predictive modeling of infrared radiative heating in tomato dry-peeling process: Part II. Model validation and sensitivity analysis. Food and Bioprocess Technology: An International Journal. 7:2005-2013.

Pan, Z., X. Li, G.Bingol, T. H. McHugh, and G. G. Atungulu. 2009. Development of infrared radiation heating method for sustainable tomato peeling. Applied Engineering in Agriculture. 25(6):935-941.

Li, X., A. Zhang, G.G. Atungulu, M. Delwiche, R. Milczarek, D. Wood, T. Williams, T.H. McHugh, and Pan. 2014. Effects of infrared radiation heating on peeling performance and quality attributes of clingstone peaches.LWT – Food Science and Technology. 55:34-42.

Related materials:

Watch a YouTube video: A pilot scale infrared dry-peeling system for tomatoes; demonstration pear peeling; demonstration tomato peeling. Read more articles at: Proud to be Green and Reducing water use in food processing.