IR heating as an environmentally friendly technology can achieve simultaneous drying, disinfestation, disinfection and stabilization of rough rice.

Drying

Rice is normally dried with hot air with low energy efficiency and long drying time. Our team has successfully developed an effective drying technology for rough rice using IR heating followed by tempering treatment and natural cooling. The drying characteristics of rice, including drying rate and quality, and energy efficiency were comprehensively studied under different design and operation conditions. The research results revealed that the infrared drying technology was superior to the conventional rice drying method, especially in terms of its higher drying rate, improved rice milling quality, and reduced environmental impact.

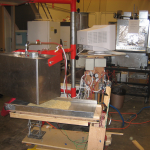

(click for original picture)

Disinfestation

Chemical fumigation is normally used for rice disinfestation. A non-chemical disinfestation method using IR heating was developed in our group. An effectiveness disinfection is achieved using IR heating to heat freshly harvested or storage rough rice to a temperature of 60 ̊C followed by tampering treatment. For harvest rice, a simultaneous drying and disinfestation of rough rice was obtained by using IR heating without using any chemicals. The IR heating for the disinfestation of storage rice caused less than 0.5% moisture loss and no milling quality change.

(click for original picture)

Disinfection

IR heating has the potential to be used as an effective disinfection method for harvest and storage rough rice and other grains. The recommended conditions of simultaneous disinfection and drying for fresh rice is to heat rice to 60°C followed by tempering for 120 min and natural cooling. The recommended condition of simultaneous disinfection and drying for storage rice was to rewet the rough rice to a MC of 19.4% (d.b.), then using IR to heat the rice to 60°C followed by 20 min of tempering and naturel natural cooling treatment. After the treatment, the final MC of rice was safe for storage.

Stabilization

Another discovery is that IR heating can achieve simultaneously drying and effective inactivation of lipase and extend shelf life of rough and brown rice. IR drying provides a potential to store brown rice instead of rough rice with extended shelf life and reduced cost. IR heating can also be used to stabilize rice bran to preserve the high nutritional and functional characteristics of components in bran, which is important before oil extraction.

Selected Publications:

Ding, C., R. Khir, Z. Pan, D.F. Wood, C. Venkitasamy, K. Ru, H. El-Mashad, and J. Berrios. 2018. Influence of infrared drying on storage characteristics of brown rice. Food Chemistry. 264:149-156. https://doi.org/10.1016/j.foodchem.2018.05.042.

Wang, T., R. Khir, Z. Pan, and Q. Yuan. 2017. Simultaneous rough rice drying and rice bran stabilization using infrared radiation heating. LWT – Food Science and Technology. 78:281-288. https://doi.org/10.1016/j.lwt.2016.12.041.

Ding, C., R. Khir, Z. Pan, D.F. Wood, K. Tu, H. El-Mashad and J. Berrios. 2016. Improvement in storage stability of infrared dried rough rice. Food and Bioprocess Technology: An International Journal. 9:1010-1020. https://doi.org/10.1007/s11947-016-1690-5.

Wang, B., R. Khir, Z. Pan, H. El-Mashad, D. Wood, N.E. Mahoney, B. Wu, and H. Ma. 2016. Simultaneous drying and decontamination of rough rice using combined pulsed light and holding treatment. Journal of the Science of Food and Agriculture. 96:2874-2881. https://doi.org/10.1002/jsfa.7458.

Ding, C., R. Khir, Z. Pan, K. Tu, L. Zhao, H. El-Mashad, and T.H. McHugh. 2015. Improvement in shelf life of rough and brown rice using infrared radiation heating. Food and Bioprocess Technology: An International Journal. 8(5): 1149-1159.