Excavation support systems are used to minimize the excavation area, to keep the sides of deep excavations stable, and to ensure that movements will not cause damage to neighboring structures or to utilities in the surrounding ground.

This photo shows a sewer excavation in San Francisco supported by a driven sheet pile wall, with pipe struts extending across the excavation. Wide flange beams distribute the loads of the pipe struts to the sheet pile walls. Because the struts are compression members, their capacities are controlled by considerations of buckling. Lateral supports reduce the effective lengths of the struts and increase their capacities.

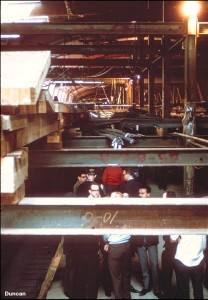

This photo shows an excavation for the BART system, beneath Shattuck Avenue in Berkeley, California. Street traffic is carried on timbers that form a roof on the excavation, while construction of the cut-and-cover tunnel goes on beneath. The work area is very constricted by the horizontal H-beam struts and the vertical supports for the roadway over head.

Here the sheet pile wall around a building excavation is supported by pipe struts. Those in the foreground, which extend from one side of the excavation to the other, are termed “cross-lot” braces. In the corner of the excavation the sheet piles are supported by corner braces. Corner braces reduce the constriction in part of the working area.

This photo shows the excavation support system for a building in the Embarcadaro Center in San Francisco. The wall is a slurry trench concrete wall (a concrete wall constructed in a slurry-supported trench in the ground). The sides of the excavation are supported by external supports — H-piles driven through holes in the wall, which work in tension to hold the wall. The use of external support greatly reduces the amount of congestion within the excavation, making construction faster and less costly. Corner braces support the corners of the excavation.

Here the wall is supported by “rakers,” or inclined struts. The bottom ends of the rakers are braced against the central part of the building foundation slab. The excavation was carried to full depth at the center first so that the foundation slab could be poured. Prior to installation of the rakers, the lower part of the slurry trench concrete wall was supported by an earth berm. The earth berm remains at the far side of the excavation.

A second, lower, set of rakers was installed after part of the berm was excavated. This photo was taken when the excavation was complete. It is interesting to see that the concrete wall, constructed in a slurry-supported trench, is very smooth and of good quality.

This photo shows the excavation support system for the Getty Center art museum garage in Los Angeles, California. The excavation is about 75 feet deep. The sides of the excavation are supported by soldier piles and lagging. The soldier piles are driven before excavation begins, and the wood lagging is installed as the excavation proceeds down. On the sides of the excavation the soldier pile and lagging wall is supported by post-tensioned anchors drilled and grouted into the soil around the excavation. The corners are supported by corner braces.

The weathered rock at the bottom of the Getty Center excavation is stiff enough to support itself without lagging.