Data-Driven Human Cyber-Physical Systems Collaboration and Digitization of Manufacturing Operations

Humans, in the role of either customers, designers, program managers, or workers, will always play a significant role in future manufacturing. The systems that the humans are collaborating with are becoming increasingly complicated especially with the rise of large-scale industrial cyber-physical systems (CPSs), also called Industrial Internet of Things (IIoT). Amazingly, we are still lacking an efficient and effective way of teaming up humans with CPSs, mainly due to adaptability and scalability issues.

Research is aimed at developing a smart analytics system for manual grinding which can transform experience-based knowledge into evidence-based decision making for sustainable operations and reliable product performance. The performance in manual grinding is highly dependent on worker experience, path control, forces, and other human-centric parameters. Our research has included attention in manual tasks as evaluated with gaze tracking, force and energy efficiency [1, 2], and different tool path strategies [3]. This research is collaborative research with Prof. Zhaodan Kong, UCD. See human sensorimotor behavior in manual grinding here: cphslab.com/research

We also employ different sensors to monitor manual operations [4]. This work is in collaboration with Professor Chih-Hsing Chu, National Tsing Hua University .

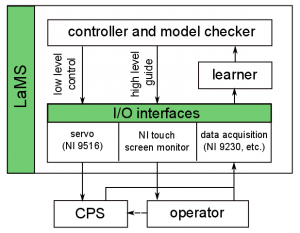

Further research with Prof. Zhaodan Kong, UCD is aimed at developing a data-driven LabVIEW-based management system (LaMS) that can manage data collection, communication between humans and the CPSs, and CPS control.

Figure: Data-driven LabVIEW-based management system. We use relevant manufacturing tasks (grinding and 3D printing) on a prototypic, modular machine tool system as a test bed and LabView as our main software to: (i) develop a way of inferring input-output relations and mining patterns from data collected from CPSs and humans (inference); (ii) develop a predictive scheme to improve the performance of the human-CPS team (predictive decision-making); (iii) Develop a monitoring, verification and synthesis method to formally guarantee and guide the team’s progress (online monitoring, formal synthesis and verification).

Figure: Data-driven LabVIEW-based management system. We use relevant manufacturing tasks (grinding and 3D printing) on a prototypic, modular machine tool system as a test bed and LabView as our main software to: (i) develop a way of inferring input-output relations and mining patterns from data collected from CPSs and humans (inference); (ii) develop a predictive scheme to improve the performance of the human-CPS team (predictive decision-making); (iii) Develop a monitoring, verification and synthesis method to formally guarantee and guide the team’s progress (online monitoring, formal synthesis and verification).

Further collaboration with Prof. Robert Schmitt, WZL, RWTH Aachen University explored how product engineers and designers can gain insights on the use phase and can derive design changes and quality improvement. We proposed a methodology to capture the most relevant data on product use and human-product interaction automatically and utilize it as part of data-driven product improvement [5].

Publications:

- Bales, G., Das, J., Tsugawa, J., Linke, B., Kong, Z.: Digitalization of Human Operations in the Age of Cyber Manufacturing: Sensorimotor Analysis of Manual Grinding Performance, Journal of Manufacturing Science and Engineering, 2017, 139(10):101011-101011-8., MANU-17-1071, doi: 10.1115/1.4037615

- Gregory Bales, Jayanti Das, Barbara Linke and Zhaodan Kong, Recognizing Gaze-Motor Behavioral Patterns in Manual Grinding Tasks, Procedia Manufacturing, 5, 106-121, 2016, https://doi.org/10.1016/j.promfg.2016.08.011

- Jayanti Das, Gregory L. Bales, Zhaodan Kong and Barbara Linke, Integrating Operator Information for Manual Grinding and Characterization of Process Performance Based on Operator Profile, J. Manuf. Sci. Eng 140(8), 081011, doi: 10.1115/1.4040266

- Kamath, B. Linke, and C. Chu, “Enabling Advanced Process Control for Manual Grinding Operations,” Smart and Sustainable Manufacturing Systems 4, no. 2 (2020): 210-230. https://doi.org/10.1520/SSMS20190045

- Voet, Henning, Altenhof, Max, Ellerich, Max, Schmitt, Robert H., Linke, Barbara, A Framework for the Capture and Analysis of Product Usage Data for Continuous Product Improvement, Journal of Manufacturing Science and Engineering, Vol. 141, 021010 (2018) (11 pages); doi:10.1115/1.4041948