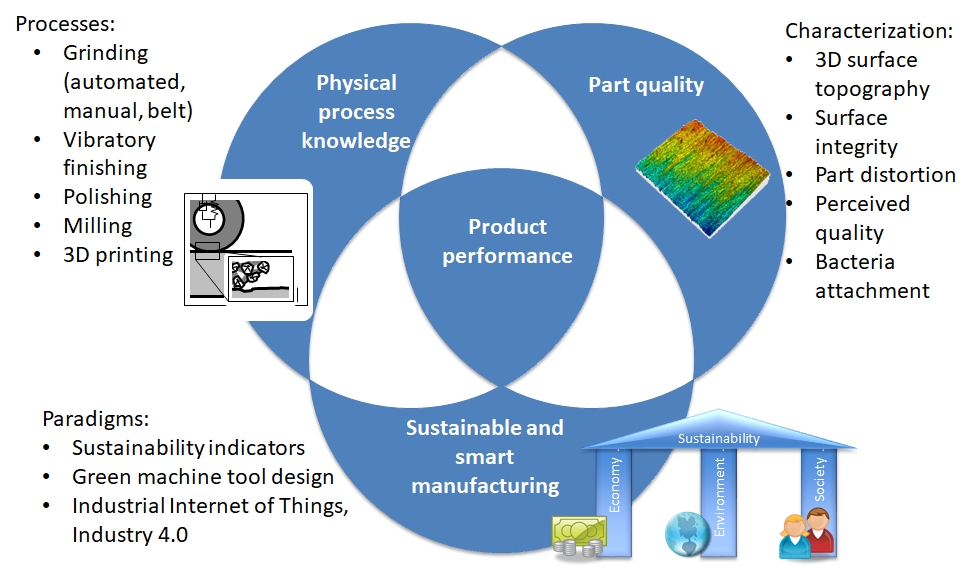

Our research is centered around product performance, with part quality and quality characterization, physical process knowledge, and sustainable and smart manufacturing in mind. Please look at the pages below to find out more about our research projects.

Projects

2014 – 2017 Optimising Turbo-Spindle Efficiency for Machining at Ultra-High Speed (OpTEMUS)

2014 – 2023 IRTG 2057 – International Research Training Group (IRTG) “Physical Modeling for Virtual Manufacturing Systems and Processes”

2015 – 2018 NSF project on Integrated STEM Approach for Studying Aerospace Engineering Design and Manufacturing

2017 – 2021 NSF/DFG Collaboration to Understand the Prime Factors Driving Distortion in Milled Aluminum

Additive Manufacturing – Applications and Sustainability

Data-Driven Human Cyber-Physical Systems Collaboration

Development of an energy-efficient cylindrical grinding machine

Environmental impacts of manufacturing operations

Modular Hybrid Desktop Machine

Surface engineering for food safety

Surface modifications for lifting surfaces and greener aviation

Surface topography and integrity after finishing operations

More projects, including Greening tool design, finding bio-inspired processes and tool designs;