More Projects

Sustainability and mechanical aspects in endoscopy

Assoc. Prof. Barbara Linke,

Dr. med. Dipl.-Phys. A. Anjali Roeth, ESCAM – European Surgical Center Aachen Maastricht, University Hospital RWTH Aachen

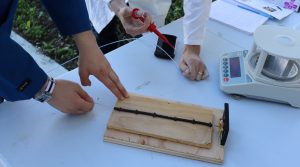

Flexible endoscopy is used in different medical fields such as internal medicine or surgery. Endoscopic forceps are important instruments for endoscopy. This research is concerned with the sustainability and performance of endoscopic biopsy forceps. A first study developed a test stand for investigating biopsy performance testing and operator behavior.

Publication:

- Linke, B., Toribio, A., Geary, S., Neumann, U.P., Roeth, A.A., Performance testing of endoscopic biopsy forceps, MSEC2018-6358, Proceedings of the ASME 2018 International Manufacturing Science and Engineering Conference MSEC2018, June 18 to June 22, 2018, College Station, Texas, USA, MSEC2018-6358, doi: 10.1115/MSEC2018-6358

Manufacturing Induced Strain and Long-Term Material Performance

Prof. Michael Hill, Assoc. Prof. Barbara Linke

Funding Body: Electric Power Research Institute, 2013 -2015

Cold-working, or strain-hardening, is a process where a material is plastically strained at a temperature well below its melting point. Often defined in terms of percent elongation or area reduction, cold work (CW) is more of an overall process than a specific property. Cold-working a part affects many material properties such as hardness and strength, which can have serious impact on its overall performance. For example, negative effects associated with cold-work lead to increased susceptibility to environmentally assisted cracking (stress corrosion cracking) in nuclear plant components. To date, evaluation of cold-work has been mainly qualitative in nature. This research project first aims to identify and evaluate test methods in order to define a quantitative measure for cold work; further work will allow accurate assessment of cold-work levels in components undergoing a multiple process chain.

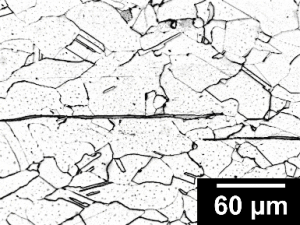

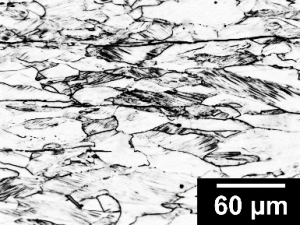

Figure: Microstructure of stainless steel as-received (left) and after 30% cold working (right). Deformation twins (dark hatching inside grains) and grain elongation are visible.

Publication:

- H. Smith, BS Linke, O Muránsky, C Hamelin, MR Hill, Assessment of Mechanical Properties and Microstructure Characterizing Techniques in Their Ability to Quantify Amount of Cold Work in 316L Alloy, Eng. Mater. Technol. 1-37 (37 pages), MATS-19-1142, 2020, https://doi.org/10.1115/1.4047024

Molecular Dynamics Analysis of Aluminum Deformation

Prof. Herbert Urbassek, Physics Department and Research Center OPTIMAS, University of Kaiserslautern,

Assoc. Prof. Barbara Linke

Plastic deformation of single- and polycrystalline aluminum was studied with molecular dynamics simulations. Pressing, holding and the release phases of nano-sized sample in vices during nanomanufacturing were analyzed.

Publication:

- Garcia, D., Zhang, Z., Linke, B., Urbassek, H., Molecular Dynamics Simulations of Single Grain Pure Aluminum in a Vice Fixture for Nanomanufacturing Applications, CIRP Journal of Manufacturing Science and Technology, https://doi.org/10.1016/j.cirpj.2018.07.005, Volume 23, November 2018, Pages 91-97

- Vardanyan, V.H., Linke, B.S. & Urbassek, H.M. Distortion of a polycrystalline Al bar in a vice fixture: molecular dynamics analysis of grain movement and rotation. Int J Adv Manuf Technol (2021). https://doi.org/10.1007/s00170-021-07641-y

New Concepts for Bio-inspired Sustainable Grinding

Bio-inspired design is a promising and innovative approach to improve the sustainability of products and processes. This research project aims to explore how nature can inspire improvements in grinding process, and in particular the use of bio-inspired design to find novel process setups for grinding system components. A first report at the NAMRC 2014 conference and journal publication addressed problems such as chip transport and tool cleaning, abrasive wear resistance, self-sharpening, breaking air barriers, cooling, and new process environments. The new bio-inspired concepts and axiomatic design approach will be validated through case studies and experimental tests.

Publication:

- Linke, B.; Moreno, J.: New Concepts for Bio-inspired Sustainable Grinding, Journal of Manufacturing Processes, Volume 19, August 2015, p.73–80, http://dx.doi.org/10.1016/j.jmapro.2015.05.008

Sustainability Indicators for Finishing Operations

Sustainability of manufacturing processes and abrasive machining is of high importance to production engineers. However, choosing and standardizing the best indicators to evaluate processes sustainability is challenging. There are many sustainability indicators available, but these indicators mostly focus on energy and material efficiency. For finishing operations, these indicators are not suitable as they often relate to the processed material removal volume, which is very small in finishing operation. More appropriate sustainability indicators for finishing operations are based on process performance and part quality.

Publication:

- Linke, B.; Das, J.; Lam, M.; Ly, C.: Sustainability Indicators for Finishing Operations based on Process Performance and Part Quality, Proceedings of the 6th CIRP International Conference on High Performance Cutting, HPC2014, Berkeley, CA, USA, June 23 – 25, 2014, http://www.sciencedirect.com/science/article/pii/S2212827114001607

- Linke, B.: Sustainability Indicators for Grinding Applied to Dressing Strategies, Journal of Manufacturing Science and Engineering, Oct. 2013, Vol. 135 / p. 054502-1 – 6, DOI: 10.1115/1.4025191, http://manufacturingscience.asmedigitalcollection.asme.org/article.aspx?articleid=1737364

- Aurich, J.C.; Linke, B.; Hauschild, M.; Carrella, M.; Kirsch, B.: Sustainability of abrasive processes, Annals of the CIRP 62/2/2013, p. 653-672, http://dx.doi.org/10.1016/j.cirp.2013.05.010

- Linke, B.; Dornfeld, D.: Application of Axiomatic Design Principles to Identify More Sustainable Strategies for Grinding, Journal of Manufacturing Systems, Vol. 31, Issue 4, October 2012, p. 412–419, http://dx.doi.org/10.1016/j.jmsy.2012.07.007

- Linke, B.; Corman, G.; Dornfeld, D.; Toenissen, S.: Sustainability indicators for discrete manufacturing processes applied to grinding technology. Journal of Manufacturing Systems 32 (2013), p. 556 – 563, http://dx.doi.org/10.1016/j.jmsy.2013.05.005

Communicating Corporate, Business and Operational Sustainability Strategies and new decision methodologies

Consumers expect manufacturing companies to act sustainably. Research has shown that companies are starting to develop and communicate their sustainability agenda, but leaving the customer wondering if and how sustainability is really executed down the line. In this project a research methodology was defined to study the sustainability goals and strategies on corporate, business and operational level. The goals and strategies are rated on their conveyance and correlation. These results are visualized in a matrix. A case study with the web-based information of 100 companies revealed that energy, waste, and diversity are the most named sustainability goals. Support for charity programs, smarter programming, reuse of waste heat, efficient lighting systems and childcare/ work time models were the most cited sustainability strategies. Ongoing studies aim to help manufacturing engineers to evaluate the sustainability of discrete manufacturing processes or broader processing strategies. A transparent method to compare and balance the different dimensions of sustainability is a key factor for the successful transfer of academic models into industry.

Publication:

- Van der Spiegel, D.; Linke, B.; Stauder, J.; Buchholz, S.: Sustainability strategies of manufacturing companies on corporate, business and operational level, Int. J. Strategic Engineering Asset Management, Vol. 2, No. 3, p. 270-286, 2015, https://www.inderscienceonline.com/doi/abs/10.1504/IJSEAM.2015.072125

Life Cycle Analysis of Grinding Tools

To understand sustainability in grinding technology, comprehensive studies on the life cycle of grinding tools are needed. Grinding tools are complex products with a life cycle of their own, including: raw material extraction, tool manufacturing, tool use and end of life. There is a large variety of grit types (spanning from conventional grits such as alumina and silicon carbide to the superabrasives cubic boron nitride and diamond), bond materials (resin, vitrified or metallic bonds), designs (wheels, pins, belts, full-body tools or with tool body, etc.) which result in numerous manufacturing routes. This research project investigates the life stages of grinding tools, while paying close attention to the wear behavior during tool usage. The supply chain of grinding tools can become more transparent to achieve more sustainable grinding tools. Leveraging effects can occur if more sophisticated tools offset their higher economic or environmental impacts through better performance in the grinding process.

Publications:

- Linke, B: Life Cycle and Sustainability of Abrasive Tools, ISBN 978-3-319-28345-6, Springer, 2016, http://www.springer.com/us/book/9783319283456

- Linke, B.: Manufacturing and Sustainability of Bonding Systems for Grinding Tools, Production Engineering – Research and Development, June 2016, Volume 10, Issue 3, pp 265–276, DOI: 10.1007/s11740-016-0668-5, https://link.springer.com/article/10.1007/s11740-016-0668-5

- Linke, B.: Sustainability Concerns in the Life Cycle of Bonded Grinding Tools, CIRP Journal of Manufacturing Science and Technology, Vol. 7, Issue 3, 2014, p. 258-263, http://dx.doi.org/10.1016/j.cirpj.2014.05.002

- Linke, B.: A review on properties of abrasive grits and grit selection, International Journal of Abrasive Technology, Int. J. of Abrasive Technology, 2015 Vol.7, No.1, pp.46 – 58, DOI: 10.1504/IJAT.2015.070582