NSF/DFG Collaboration to Understand the Prime Factors Driving Distortion in Milled Aluminum Workpieces

Project duration: 04/15/2017 to 09/30/2021

Graduate students Destiny Garcia, Renan Ribero, Christopher D’Elia, Christopher Chighizola, Nicholas Bachus, Julianne Emily Jonsson

Assoc. Prof. Barbara Linke, Professor Michael Hill

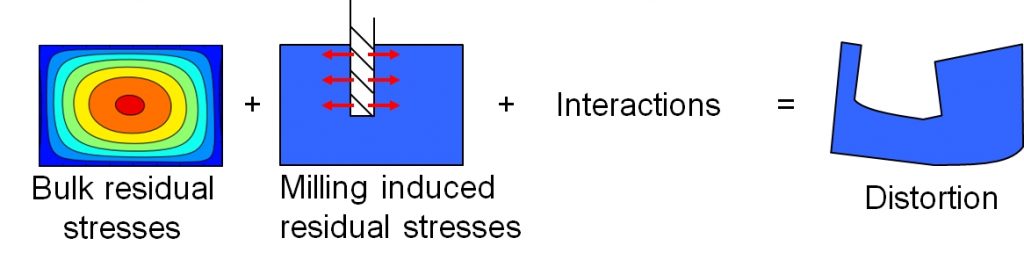

Distortion in manufacturing is a defined as the deviation of a part shape from original intent after released from the fixture. In machining, there are two main causes of part distortion:

- Machining induced distortion driven into the workpiece from a cutting tool

- Bulk residual stress induced distortion in which there is a rebalance of residual stress from re-equilibration due to material removal.

Figure 1 Hypothesis on machining distortion mechanism

Figure 1 Hypothesis on machining distortion mechanism

This research tests the hypothesis that distortion of thin walled monolithic workpieces during milling can be predicted and controlled from understanding bulk residual stresses and machining residual stresses. We study bulk residual stresses, machining residual stresses, and their superposition through well defined experimental and modeling work at UC Davis and at TU Kaiserslautern at Prof. Dr.-Ing. Jan C. Aurich’s Institute for Manufacturing Technology and Production Systems (FBK).

Publications:

[1] Destiny R. Garcia, Michael R. Hill, Jan C. Aurich and Barbara S. Linke, Characterization of Machining Distortion due to Residual Stresses in Quenched Aluminum, ASME 2017 12th International Manufacturing Science and Engineering Conference, Los Angeles, California, USA, June 4–8, 2017 (link)

[2] Barbara Linke, Michael Hill, Christopher R D’Elia, Renan Luiz Ribeiro, Destiny Garcia, Jan C. Aurich, Benjamin Kirsch, Daniel Weber, NSF/DFG Collaboration to Understand the Prime Factors Driving Distortion, Poster MSEC2018-6746, ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, Texas, USA, June 18-22, 2018

[3] Chighizola, C., D’Elia, C., Weber, D., Kirsch, B., Aurich, J., Linke, B., Hill, M., Intermethod Comparison and Evaluation of Measured Near Surface Residual Stress in Milled Aluminum, Experimental Mechanics, 61, 1309–1322 (2021). https://doi.org/10.1007/s11340-021-00734-5

[4] Weber, B. Kirsch, C. Chighizola, C. D’Elia, B. Linke. M. Hill, J. Aurich, Analysis of machining-induced residual stresses of milled aluminum workpieces, their repeatability, and their resulting distortion, The International Journal of Advanced Manufacturing Technology, (), 1-22, 2021, http://link.springer.com/article/10.1007/s00170-021-07171-7

[5] Garcia, B. Linke, R. Farouki, Optimized Routine of Machining Distortion Characterization based on Gaussian Surface Curvature, Vol. 89, iPMVM 2020, 2021, DOI: 10.4230/OASIcs.iPMVM.2020.5

[6] Weber, B. Kirsch, C. Chighizola, J. Jonsson, C. D’Elia, B. Linke. M. Hill, J. Aurich, Finite element simulation combination to predict the distortion of thin walled milled aluminum workpieces as a result of machining induced residual stresses, Vol. 89, iPMVM 2020, 2021, DOI: 10.4230/OASIcs.iPMVM.2020.11

[7] J.E. Jonsson, M.R. Hill, C.R. Chighizola, C.R. D’Elia, B.S. Linke, D. Weber, B. Kirsch, J.C. Aurich: Milling-Induced Residual Stress and Distortion Under Variations of Bulk Residual Stress. Proceedings of the 31st ASM Heat Treating Society Conference (2021): S. 96-99

[8] Weber, B. Kirsch, C.R. Chighizola, C.R. D’Elia, B.S. Linke, M.R. Hill, J.C. Aurich: Investigation on the scale effects of initial bulk and machining induced residual stresses of thin walled milled monolithic aluminum workpieces on part distortions: experiments and finite element prediction model. Procedia CIRP 102 – Proceedings of the 18th CIRP Conference on Modeling of Machining Operations (2021): S. 337-342.

[9] Chighizola, C. R. and Hill, M. R.. (2022). Two-dimensional Mapping of Bulk Residual Stress Using Cut Mouth Opening

Displacement. Experimental Mechanics. 62, doi:https://doi.org/10.1007

[10] Chighizola, Christopher R. and D’Elia, Christopher R. and Hill, Michael R.. (2019). Intermethod comparison and evaluation of

near surface residual stress in aluminum parts subject to various milling parameters. Residual Stress, Thermomechanics &

Infrared Imaging and Inverse Problems, Volume 6; Proceedings of the 2019 Annual Conference on Experimental and

Applied Mechanics. doi:10.1007/978-3-030-30098-2

[11] Weber, D. and Kirsch, B. and D’Elia, C.R. and Linke, B.S. and Hill, M.R. and Aurich, J.C.. (2019). Concept to analyze

residual stresses in milled thin walled monolithic aluminum components and their effect on part distortion. Production at the

leading edge of technology – Proceedings of the 9th Congress of the German Academic Association for Production

Technology. 287-296.

[12] Jonsson, J.E., Chighizola, C.R., D’Elia, C.R., Hill, M.R., Linke, B.S., Weber, D., Kirsch, B., Aurich, J.C. (2021). Wafer

Experiments to Assess Machining Distortion in Aluminum (Poster). 2021 MSEC Manufacturing Science and Engineering

Conference of ASME, virtual, hosted by the University of Cincinnati, OH. Best poster award

This project is funded by the National Science Foundation under Award No. 1663341 (Division of Civil, Mechanical and Manufacturing Innovation, Manufacturing Machines and Equipment (MME)).

This project is funded by the National Science Foundation under Award No. 1663341 (Division of Civil, Mechanical and Manufacturing Innovation, Manufacturing Machines and Equipment (MME)).

Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

The TU Kaiserslautern project is funded by the German Research Foundation (DFG).